FIELD SERVICE BULLETIN NO. 11

Retrofit for MicroCATs with Integral

Pumps (37-IMP, 37-SMP, 37-SIP)

Retrofit for MicroCATs with Integral

Pumps (37-IMP, 37-SMP, 37-SIP)

December 2006

Equipment Affected

All 37-IMP, 37-SMP, 37-SIP MicroCATs shipped before

mid-December, 2006.

Note: This Field Service Bulletin does

not apply to MicroCATs without an integral pump (SBE 37-IM, 37-SM,

37-SI).

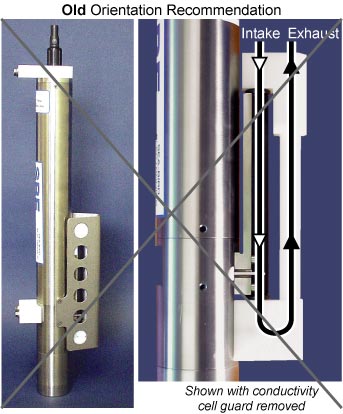

Description of Problem

|

When deployed near the sea bottom or in very turbid

waters, pumped MicroCATs oriented with the intake/exhaust plumbing in an upright

U-shape can become clogged with sediment. This results in poor flushing, causing

poor quality data.

Reversing the orientation by putting the intake/exhaust

plumbing pointing downward will prevent sediment from accumulating, but will

cause air to be trapped in the pump impeller housing, thus preventing the pump

from priming quickly at depths above approximately 30 meters. Trapped air could

result in poor data until the air eventually dissolves and allows the pump to

prime and normal flushing to begin.

|

|

Solution

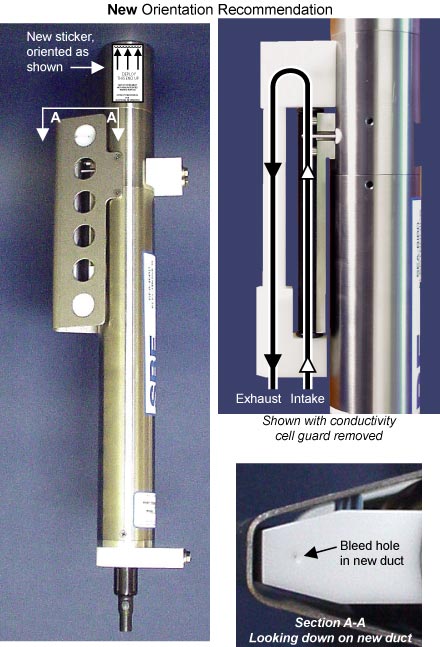

| Sea-Bird now recommends that the MicroCAT be oriented for

deployment with its intake / exhaust in an inverted U-shape, with the

intake/exhaust plumbing pointing downward. A minor design modification has been

implemented to allow trapped air to escape. Sea-Bird is providing a replacement duct with a small air

bleed hole. The bleed hole allows any air in the plumbing to escape. Retrofit is

easy and simply requires:

- Replacing the old duct with a new one having the air

bleed hole.

- Removing the old orientation sticker and applying the

new one, with the MicroCAT oriented as shown here, and the arrows on the

sticker pointing up.

|

|

Corrective Action by Sea-Bird

- MicroCATs shipped before mid-December 2006:

- Sea-Bird will install the new duct with air bleed hole and new orientation

sticker (at no charge) the next time the instrument is returned to Sea-Bird

for calibration or repairs.

- Alternatively, you can request that Sea-Bird send you the retrofit kit (at

no charge), PN 50420 Pumped MicroCAT Duct with Air Bleed Hole Retrofit Kit,

if you want to do the retrofit yourself before you are able to send the

MicroCAT in for calibration or other repairs. Replace the duct and the

orientation sticker.

- MicroCATs shipped in mid-December 2006 and later: The

new duct with air bleed hole and orientation sticker are already installed.

Background Information and Detailed Deployment

Recommendations

Background Information

The integral pump runs for 1/2 second each time the

MicroCAT takes a sample. This pumping scheme, combined with the plumbing’s

U-shape, provide the following advantages over a non-pumped system:

- Improved conductivity response – The pump flushes the

previously sampled water from the conductivity cell and brings a new water

sample quickly into the cell.

- Reduced biological fouling – Water does not freely flow

through the conductivity cell between samples, allowing the build-up of the

anti-foulant in the water held in the plumbing, and minimizing fouling.

We recognize from discussions with some customers that the

original recommendations for MicroCAT orientation allow the MicroCAT to trap too

much sediment. This problem occurs mostly in shallow coastal waters, near-bottom

moorings, or offshore plumes of large rivers.

Deploying in an inverted U-shape to reduce the

ingestion of materials presents a different challenge – how to eliminate air

from the system, so that the pump will prime and operate. In considering the

effect of air on the pump, it can be instructive to look at the amount of air in

the water column:

- Case 1: The top ~2 meters of the water column

may contain a continuous supply of bubbles injected into the system by

breaking waves. In this area, the ability to continuously eliminate air from

the system, throughout the deployment, is of prime concern.

- Case 2: The next ~30 meters of the water column

is not typically affected by bubbles from breaking waves. In this region, it

could take a few days to weeks after deployment for the air to clear out of

the system in an inverted U-shape. However, once the air is bled, no more air

would be injected into the plumbing.

- Case 3: Below ~30 meters, it could take only a

few hours to a day for the air to clear out of the system in an inverted

U-shape. As in Case 2, once the air is bled, no more air would be injected

into the plumbing.

To allow use of the MicroCAT in the inverted

U-shape, Sea-Bird has designed a new duct with a small air bleed hole, to

provide a way for the air to exit the plumbing. However, because the bleed hole

also provides a little more ventilation of the system, this ventilation will

cause a slight decrease in the concentration of anti-foulant in the water held

in the plumbing between samples. In our judgment, and the experience of

customers, the risk of poor data due to sediment accumulation is usually greater

than the risk of slightly reduced effectiveness of the anti-foulant, or is at

least a reasonable trade-off.

Recommendations for Deployment

- Most deployments – Using the new duct with air

bleed hole, deploy the MicroCAT on a mooring cable or structure with the

plumbing in an inverted U-shape, allowing air to exit the plumbing

through the bleed hole.

- Deployments where severe bio-fouling is the main

concern and sediment is not an issue –

Case A: You need accurate data

immediately upon deployment ‑

Do not retrofit your existing MicroCAT (alternatively, plug the bleed hole in

a MicroCAT that has been retrofitted). Deploy the MicroCAT with the plumbing

in an upright U-shape, providing maximum bio-foul protection but

leaving the MicroCAT vulnerable to ingestion of sediment.

Case B: You can skip some initial data, allowing time for trapped air to

dissolve into the water and the pump to prime properly – Do not retrofit your

existing MicroCAT (alternatively, plug the bleed hole in a MicroCAT that has

been retrofitted). Deploy the MicroCAT with the plumbing in an inverted

U-shape, providing maximum bio-foul protection as well as protection from the

ingestion of sediment. This deployment method will provide good data within a

day if the deployment is deeper than ~30 meters. Eliminate scans associated

with the initial deployment by evaluating the conductivity data; minimal

changes in conductivity are an indication that the pump flow is not correct

because air in the plumbing has prevented the pump from priming.

- Deployments where air bubbles are the main concern

and sediment is not an issue ‑ Do not retrofit your existing MicroCAT

(alternatively, plug the bleed hole in a MicroCAT that has been retrofitted).

Deploy the MicroCAT with the plumbing in an upright U-shape. This

orientation provides better bleeding of air from the plumbing than can be

achieved with the small bleed hole, but leaves the MicroCAT vulnerable to

ingestion of sediment.

Cleaning the Air Bleed Hole before each Deployment

The air bleed hole is 0.5 mm (0.02 inch) diameter. Clean

the air bleed hole before each new deployment, using a 0.4 mm diameter wire, 13

mm long (0.016 inch diameter wire, 0.5 inches long) (you can use #26 AWG wire).

Clean the hole and blow through it to ensure it is open and can vent trapped air

upon deployment.

Print version of

this Field Service Bulletin in Adobe Acrobat .pdf format

Last modified:

06 Apr 2007

Sea-Bird Home Phone: 425-643-9866

Fax: 425-643-9954 E-mail:

seabird@seabird.com

![]() Retrofit for MicroCATs with Integral

Pumps (37-IMP, 37-SMP, 37-SIP)

Retrofit for MicroCATs with Integral

Pumps (37-IMP, 37-SMP, 37-SIP)![]()

![]()