APPLICATION NOTE NO. 57

I/O Connector Care and Installation

Revised May 2003

Application

note in pdf format

The Application Note describes the proper care and installation of standard

I/O connectors for Sea-Bird CTD instruments. Once properly installed, the connections

require minimal care. Unless access to the bulkhead is required, the connections can be

left in place indefinitely. The Application Note is divided into three sections:

Carefully clean the bulkhead connector and the inside of the

mating inline (cable end) connector with a Kimwipe. Remove all grease, hair, dirt, and other contamination.

|

Clean bulkhead connector |

Clean inside of connector |

- Inspect the connectors:

- Inspect the pins on the bulkhead connector for signs of

corrosion. The pins should be bright and shiny, with no discoloration. If the pins are discolored or corroded, clean

with alcohol and a Q-tip.

- Inspect the bulkhead connector for chips, cracks, or

other flaws that may compromise the seal.

- Inspect the inline connector for cuts, nicks, breaks, or other problems

that may compromise the seal.

Replace severely corroded bulkhead connectors -- contact SBE for

instructions, or a Return Authorization Number (RMA number).

Corroded pins on bulkhead connectors -- Connector on right has a missing

pin

- Using a tube of 100% silicone grease (Dow DC-4 or equivalent),

squeeze approximately half the size of a pea onto the end of your finger.

CAUTION: Do not use WD-40 or other petroleum-based lubricants, as they

will damage the connectors.

100% silicone grease

- Apply a light, even coating of grease to the molded ridge around the base of the

bulkhead connector. The ridge looks like an o-ring molded into the bulkhead connector base and fits into the groove

of the mating inline connector.

Apply grease to molded ridge

Mate the inline connector to the bulkhead, being careful to

align the pins with the sockets. Do not twist the inline connector on the bulkhead connector. Twisting can lead to bent pins, which will

soon break.

Push the connector all the way onto the bulkhead. There may be an audible pop, which

is good. With some newer cables, or in cold weather, there may not be an initial audible pop.

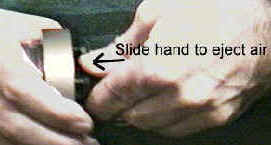

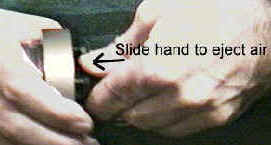

- After the cable is mated, run your fingers along the inline connector

toward the bulkhead, milking any trapped air out of the connector. You should hear the air being ejected.

CAUTION: Failure to eject the trapped air will result in the connector

leaking.

After the connectors are mated, install the locking sleeve.

The locking sleeve secures the inline connector to the bulkhead connector and

prevents the cable from being inadvertently removed.

Important points regarding locking sleeves:

- Tighten the locking sleeve by hand. DO NOT use a wrench or pliers to tighten the locking sleeve.

Overtightening will gall the threads, which can

bind the locking sleeve to the bulkhead connector. Attempting to remove a tightly bound locking sleeve may

instead result in the bulkhead connector actually unthreading from the end cap. A loose

bulkhead connector will lead to a

flooded instrument. Pay particular attention when removing a locking sleeve to

ensure the bulkhead

connector is not loosened.

- It is a common misconception that the locking sleeve provides

watertight integrity. It does not, and continued re-tightening of the locking sleeve will not

fix a leaking connector.

- As part of routine maintenance at the end of every

cruise, remove the locking sleeve, slide it up the cable, and rinse the

connection

(still mated) with fresh water. This will prevent premature cable failure.

In cold weather, the connectors may be hard to install and

remove.

Removing a frozen inline connector:

- Wrap the connector with a washrag or other cloth.

- Pour hot water on the cloth and let the connector sit for a minute or two. The connector

should thaw and become flexible enough to be removed.

Installing an inline connector:

When possible, mate connectors in warm environments before the cruise and leave them

connected.

If not,

warm the connector sufficiently so it is flexible. A

flexible connector will install properly.

By following these procedures, you will have many years of

reliable service from your cables!

Last modified:

06 Apr 2007

Sea-Bird Home Phone: 425-643-9866

Fax: 425-643-9954 E-mail:

seabird@seabird.com

![]()

![]()