APPLICATION NOTE NO.

75

Maintenance of SBE 5T and 5M Pumps

August 2004

Application note in

pdf format

| This application note is intended to assist

you in maintaining your SBE 5T

or SBE 5M pump. A properly maintained pump will provide

constant flow for your CTD and any pumped auxiliary sensors, resulting in

high quality data. The main symptom of a non-functioning or poorly

functioning pump is bad conductivity data, because the pump is not pulling

water through the conductivity cell. CAUTION: Do

not run the pump dry. The pump is water lubricated; running it without

water will damage it. If testing your system in dry conditions, remove the

Tygon tubing from the hose barb at the top of the pump head, and fill the

inside of the pump head with water. This will provide enough lubrication to

prevent pump damage during testing.

The application note is organized as follows:

|

|

At the end of a day of taking casts:

- Remove the Tygon tubing from the pump head’s hose barbs.

- Leaving the pump head on the housing, thoroughly rinse the

inside of the pump head, pouring clean, fresh water through a hose barb. If

the pump head is not rinsed between uses, salt crystals may form on the

impeller. Over time, this may freeze the impeller in place, preventing

the pump from working.

- Replace the Tygon tubing on the hose barbs.

- Unscrew the cable locking sleeve from the bulkhead

connector, and slide it up the cable. Thoroughly rinse the cable connection

(still mated) with clean, fresh water. This will prevent premature cable

failure.

- Slide the locking sleeve back into place, and screw it back

onto the bulkhead connector. Do not use a wrench or pliers to tighten the

locking sleeve.

SBE 5T

If you are going to store the pump for more than 1 week, or

have removed the pump from a mooring, perform a more thorough cleaning:

- Unscrew the pump head from the housing.

- Using clean, fresh water, thoroughly rinse the pump head

and impeller.

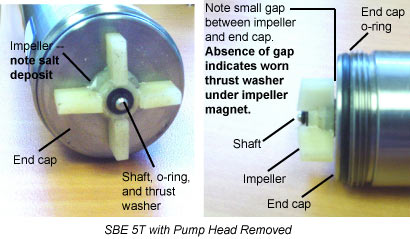

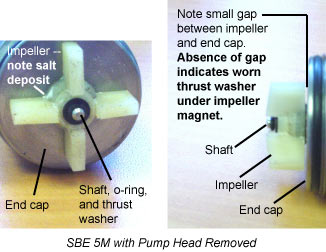

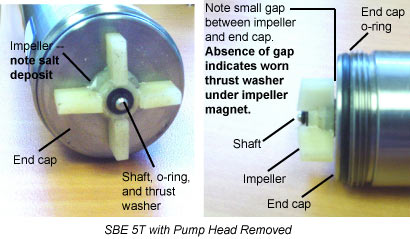

- Inspect the impeller for salt deposits. Clean any deposits

with clean, fresh water and a toothbrush. Verify that the impeller can turn

freely.

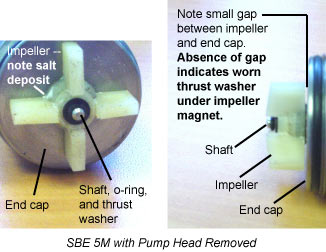

- Inspect the shaft, and the o-ring and thrust washer holding

the impeller on the shaft. There is another thrust washer underneath the

impeller magnet, inside the housing. If this thrust washer is in good

condition, you should observe a small gap between the bottom of the impeller

and the end cap. If there is no gap, the thrust washer is worn and needs to be

replaced (see Yearly Maintenance for SBE 5T for replacement procedure).

- Unscrew the pump head from the housing.

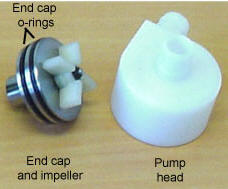

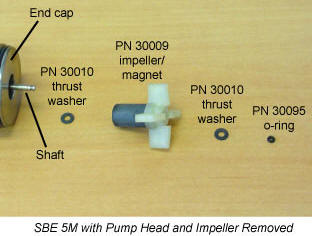

- Replace the o-ring and 2 thrust washers on the shaft:

- Remove the o-ring from the shaft. A pair of tweezers

works well for this.

- Pull the impeller and attached magnet off the shaft. The

thrust washer above the impeller will come off at the same time. Inspect the

impeller for salt build-up, and clean if necessary. Inspect the magnet for

wear. Particularly in sandy coastal environments, the magnet may be worn

down from abrasion. If necessary, replace the impeller / magnet assembly (PN

30009).

- Remove the second thrust washer from the bottom of the

shaft. A pair of tweezers works well for this.

- Inspect the shaft for wear.

- Rinse the shaft and depression in the housing with clean,

fresh water. Allow to dry.

- Using new thrust washers (2 of PN 30010) and o-ring (PN

30095), replace the thrust washer and impeller / magnet on the shaft.

Replace the other thrust washer and o-ring on the shaft, above the impeller,

pushing hard with your fingertip to seat the thrust washer and o-ring in

place.

- Inspect the end cap o-ring and the mating surface on the

pump head for dirt, nicks, and cuts. Clean or replace as necessary. Apply a

light coat of o-ring lubricant (Parker Super O Lube) to the o-ring and mating

surfaces.

- Reinstall the pump head on the pump housing.

- Inspect the bulkhead connector for corrosion, which is a

sign of seawater leakage between the bulkhead connector and cable. If there is

corrosion, thoroughly clean the connector with water, followed by alcohol.

Inspect the bulkhead connector for chips, cracks, or other flaws that may

compromise the seal. Inspect the mating cable’s connector for cuts, nicks,

breaks, or other problems that may compromise the seal. Give the connector

surfaces a light coating of silicon grease, and remate the connector

properly; see Application Note 57: I/O Connector Care and Installation.

- If the bulkhead connector is severely corroded or

damaged, it must be replaced. Sea-Bird recommends that this work be

performed at the factory, because the pump’s physical configuration makes

customer-replacement of the connector difficult.

Perform

the inspection procedures listed above in Yearly Maintenance for SBE 5T.

If you do not discover the problem there, proceed as follows.

Perform

the inspection procedures listed above in Yearly Maintenance for SBE 5T.

If you do not discover the problem there, proceed as follows.

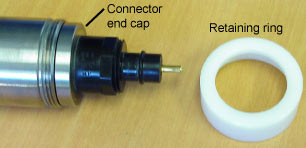

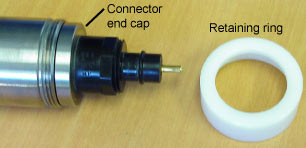

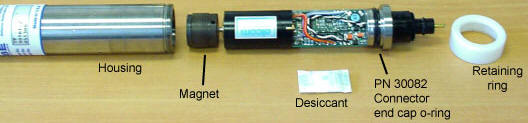

- Unscrew the connector end cap retaining ring. Pull out the

end cap and attached electronics from the housing.

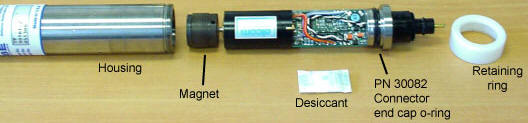

- Verify that the magnet can spin freely and is not broken or

damaged.

- Look for other signs of damage on the electronics.

- Inspect the connector end cap o-ring and the mating surface

in the housing for dirt, nicks, and cuts. Clean as necessary. If the o-ring or

mating surface is damaged, return the pump to Sea-Bird for repairs.

- Sea-Bird recommends that connector end cap o-ring

replacement be performed at the factory, because the pump’s physical

configuration makes customer-replacement of this o-ring difficult to perform

without special tools.

- Apply a light coat of o-ring lubricant (Parker Super O

Lube) to the o-ring and mating surfaces. Gently place a new desiccant bag

on the electronics (see Application Note 71 for

desiccant use and regeneration). Reinstall the electronics in the housing,

until the o-ring has fully seated. Reinstall the retaining ring on the

connector end cap.

SBE 5M

If you are going to store the pump for more than 1 week, or

have removed the pump from a mooring, perform a more thorough cleaning:

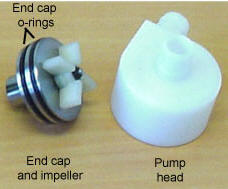

CAUTION: Remove the end cap and impeller from the housing

before cleaning the impeller. The end cap o-rings seal the electronics

chamber. The end cap may walk out of the housing after the pump head is removed,

allowing water to enter the electronics chamber if you clean the impeller

without first removing the end cap from the housing.

-

Unscrew the pump head from the housing.

Unscrew the pump head from the housing.

- Pull out the end cap from the housing.

- Using clean, fresh water, thoroughly rinse the pump head

and impeller.

- Inspect the impeller for salt deposits. Clean any deposits

with clean, fresh water and a toothbrush. Verify that the impeller can turn

freely.

- Inspect the shaft, and the o-ring and thrust washer holding

the impeller on the shaft. There is another thrust washer underneath the

impeller magnet, inside the housing. If this thrust washer is in good

condition, you should observe a small gap between the bottom of the impeller

and the end cap. If there is no gap, the thrust washer is worn and needs to be

replaced (see Yearly Maintenance for SBE 5M for replacement procedure).

- Apply a light coat of o-ring lubricant (Parker Super O

Lube) to the o-ring and mating surfaces. Reinstall the end cap in the housing,

carefully aligning the end cap with the housing and pushing hard on the end

cap to seat the first o-ring in the housing (only 1 o-ring should now be

visible).

CAUTION: If you are not careful, you may pinch the o-ring, which may

allow water to enter the housing, damaging the electronics.

- Reinstall the pump head on the end cap.

CAUTION: Remove the end cap and impeller from the housing

before cleaning the impeller. The end cap o-rings seal the electronics

chamber. The end cap may walk out of the housing after the pump head is removed,

allowing water to enter the electronics chamber if you clean the impeller

without first removing the end cap from the housing.

- Unscrew the pump head from the housing.

- Pull out the end cap from the housing.

- Replace the o-ring and 2 thrust washers on the shaft:

- Remove the o-ring from the shaft. A pair of tweezers

works well for this.

- Pull the impeller and attached magnet off the shaft. The

thrust washer above the impeller will come off at the same time. Inspect the

impeller for salt build-up, and clean if necessary. Inspect the magnet for

wear. Particularly in sandy coastal environments, the magnet may be worn

down from abrasion. If necessary, replace the impeller / magnet assembly (PN

30009).

- Remove the second thrust washer from the bottom of the

shaft. A pair of tweezers works well for this.

- Inspect the shaft for wear.

- Rinse the shaft and depression in the housing with clean,

fresh water. Allow to dry.

- Using new thrust washers (2 of PN 30010) and o-ring (PN

30095), replace the thrust washer and impeller / magnet on the shaft.

Replace the other thrust washer and o-ring on the shaft, above the impeller,

pushing hard with your fingertip to seat the thrust washer and o-ring in

place.

- Inspect the end cap o-rings and the mating surface on the

pump head for dirt, nicks, and cuts. Clean or replace as necessary. Apply a

light coat of o-ring lubricant (Parker Super O Lube) to the o-rings and mating

surfaces.

- Reinstall the end cap in the housing, carefully aligning

the end cap with the housing and pushing hard on the end cap to seat the first

o-ring in the housing (only 1 o-ring should now be visible).

CAUTION: If you are not careful, you may pinch the o-ring, which may allow

water to enter the housing, damaging the electronics.

- Reinstall the pump head on the end cap.

- Inspect the bulkhead connector for corrosion, which is a

sign of seawater leakage between the bulkhead connector and cable. If there is

corrosion, thoroughly clean the connector with water, followed by alcohol.

Inspect the bulkhead connector for chips, cracks, or other flaws that may

compromise the seal. Inspect the mating cable’s connector for cuts, nicks,

breaks, or other problems that may compromise the seal. Give the connector

surfaces a light coating of silicon grease, and remate the connector

properly; see Application Note 57: I/O Connector Care and Installation.

- If the bulkhead connector is severely corroded or

damaged, it must be replaced. Sea-Bird recommends that this work be

performed at the factory, because the pump’s physical configuration makes

customer-replacement of the connector difficult.

Perform the inspection procedures listed above in Yearly

Maintenance for SBE 5M. If you do not discover the problem there, proceed as

follows.

- Unscrew the pump head from the housing.

- Pull out the end cap from the housing.

- Pull out the electronics from the housing. Note that the

electronics are wired to the bulkhead connector inside the housing.

- Verify that the magnet can spin freely and is not broken or

damaged.

- Look for other signs of damage.

- Apply a light coat of o-ring lubricant (Parker Super O Lube)

to the o-ring and mating surfaces. Reinstall the electronics in the housing.

Reinstall the end cap in the housing, carefully aligning the end cap with the

housing and pushing hard on the end cap to seat the first o-ring in the housing

(only 1 o-ring should now be visible).

CAUTION: If you are not careful, you may pinch the o-ring, which may allow

water to enter the housing, damaging the electronics.

- Reinstall the pump head on the end cap.

Last modified:

06 Apr 2007

Sea-Bird Home Phone: 425-643-9866

Fax: 425-643-9954 E-mail:

seabird@seabird.com

![]()

Perform

the inspection procedures listed above in Yearly Maintenance for SBE 5T.

If you do not discover the problem there, proceed as follows.

Perform

the inspection procedures listed above in Yearly Maintenance for SBE 5T.

If you do not discover the problem there, proceed as follows.

Unscrew the pump head from the housing.

Unscrew the pump head from the housing.

![]()